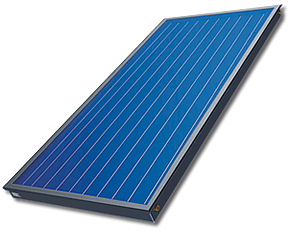

Solar Thermal Collectors

|

|

| COLLECTOR CHARACTERISTICS | LİMPİA C24 |

| Absorptive Sheet & Surface Covering | Selective Covered Copper Band 0,12 mm |

| Manifold & Absorber Pipe Material | Copper |

| Welding Type of Absorptive Sheet & Absorber Pipe | Ultrasonic |

| Surface Veil | Low-Ironed Tempered Glass |

| Base & Colleteral Lagging | Rock - Wool & Airconditioning Wlate |

| Leakproofing | Epdm & Silicon |

| Dimensions | 1991*1221*92 mm |

| Manifold & Absorber Pipe Total | 2 & 10 Pieces |

| Manifold & Absorber Pipe’s Diameter | Ø 18,0 & Ø 8,0 mm |

| Flow | 120 lt/h |

| Test & Maximum Working Pressure | 20 bar & 10 bar |

| Case | Electrostatic Painted Aluminium |

| Base Wlate | Embossed Aluminium |

|

|

| COLLECTOR CHARACTERISTICS | LİMPİA C20 |

| Absorptive Sheet & Surface Covering | Selective Covered Copper Band 0,12 mm |

| Manifold & Absorber Pipe Material | Copper |

| Welding Type of Absorptive Sheet & Absorber Pipe | Ultrasonic |

| Surface Veil | Low-Ironed Tempered Glass |

| Base & Colleteral Lagging | Rock - Wool & Airconditioning Wlate |

| Leakproofing | Epdm & Silicon |

| Dimensions | 1991*1044*92 mm |

| Manifold & Absorber Pipe Total | 2 & 9 Pieces |

| Manifold & Absorber Pipe’s Diameter | Ø 18,0 & Ø 8,0 mm |

| Flow | 102 lt/h |

| Test & Maximum Working Pressure | 20 bar & 10 bar |

| Case | Electrostatic Painted Aluminium |

| Base Wlate | Embossed Aluminium |

|

|

| COLLECTOR CHARACTERISTICS | LİMPİA C20 |

| Absorptive Sheet & Surface Covering | Selective Covered Copper Band 0,12 mm |

| Manifold & Absorber Pipe Material | Copper |

| Welding Type of Absorptive Sheet & Absorber Pipe | Ultrasonic |

| Surface Veil | Low-Ironed Tempered Glass |

| Base & Colleteral Lagging | Rock - Wool & Airconditioning Wlate |

| Leakproofing | Epdm & Silicon |

| Dimensions | 1930*930*92 mm |

| Manifold & Absorber Pipe Total | 2 & 8 Pieces |

| Manifold & Absorber Pipe’s Diameter | Ø 18,0 & Ø 8,0 mm |

| Flow | 88 lt/h |

| Test & Maximum Working Pressure | 20 bar & 10 bar |

| Case | Electrostatic Painted Aluminium |

| Base Wlate | Embossed Aluminium |

| Features, that would be changed according to customers’ claim |

| Solar Glass : Low ironed tempered prismatic designed glass, minimizes the reflection of sun-ray, and maximizes sun-ray lead in, the collector. Through this, increases the collector efficiency. Prismatic designed glass, is manufactured at best facility and has one of the best performance collector glass in Europe. |

| Absorber Sheet : The selective absorptive surface from; titanium nitrite-oxyde covered copper, is used at LIMPIA collectors, minimize the reflective loss which decreases the efficiency, and transfers the maximum ratio of radiaton heat from sun, to the plate. |

| Chasis Profile : The chasis, used in LIMPIA collectors, is specially designed and patented. |

| Glass Gasket : At LIMPIA collectors, for preventing water-enter, inside of the collector because of rain or snow reasons, UV-resistant Epdm gaskets are used as glass holder gasket. For the leakage possibility at the corners, glass gaskets provide complete leakproofing. |

| Manifold Gasket : At LIMPIA collectors, for preventing water-enter, inside of the collector because of rain or snow reasons, UV-resistant Epdm gaskets are used as glass holder gasket. For the heat differences possibility at manifold, Epdm gaskets provide complete resistant. |

| Isolation : At LIMPIA solar collectors, high heat insulated and high density 50 mm thickness rock-wool is used. And at the borders of chasis, 20 mm climate panel is used. |

| Lower Cover : At LIMPIA solar collectors; resistant to external factors and 0,40 mm thickness; hardened, embossed, aluminum sheet is used. Aluminum sheet provides highest resistant according to external factors, like; transportation, installation, wind, snow, rain and temperature. |

| Ultrasonic Welding Technology : At LIMPIA solar collectors, for integrating of surface absorber and conveyor pipes, ultrasonic welding technology are being used. |